In a world where construction, mining, and other geotechnical projects are rapidly evolving, making the right choice when it comes to tools isn't always straightforward. This is especially true when it involves rock drilling tools.

As experts in the field of rock drilling, we understand that it's essential to choose the correct tools, not only to execute the job efficiently but also to ensure the safety of your team. Selecting the ideal rock drilling tool has a substantial impact on the drilling productivity, the lifespan of the tool, and the overall cost of your project. This article aims to guide you through the integral process of recognizing the right rock drilling tool for your specific project.

When choosing a rock drilling tool, you need to consider several factors. Firstly, it's vital to understand the rock's nature you'll be drilling. Different rock formations demand different tools. For example, a tool efficient in soft rock formations might not work effectively for hard rock formations, which could lead to increased wear and tear and decrease the tool's overall lifespan.

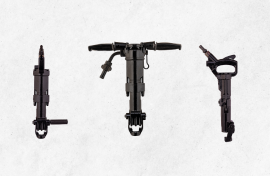

Most rock drilling tools are categorized under two main groups: rotary and percussion. Rotary tools, such as trichomes or drag bits, are ideal for softer formations as they use a cutting or scraping motion to break the rock. On the other hand, percussion tools, like hammers and jackhammers, are designed for harder rock types as they utilize an impact motion to break and penetrate the rock. The second crucial consideration is depth and size of the hole you want to drill. Holes with a smaller diameter may call for a different tool than those with a larger one. For deep drilling, a tool with a strong, durable bit is essential.

The third, but equally important, factor is the type of drilling equipment you have in place. Some rock drilling tools can only be used with specific drilling machinery. Hence, knowing your machinery's capabilities is essential when choosing your tools. Understanding the exact requirements of your project and having an in-depth knowledge of the job site can help you decide on the best rock drilling tools. Often, you may find it advantageous to get professional advice to select the appropriate tools.

It is also important to remember that using high-quality rock drilling tools can significantly improve the efficiency of your operations. Using low-quality tools may save money in the short-run but can end up costing more due to the frequency of repairs, replacements, and possible project delays.

Remember, the right rock drilling tools are not merely ones that do the job but do so in a way that maximizes efficiency and reduces costs while ensuring safety. We hope this guide aids you in making an informed choice for your project.